Concrete Slab Lifting Process

Scroll to see the 7 step process for how concrete slab lifting raises a sunken driveway.

Step 01

Concrete Slab Lifting Product

After assessing the slab, holes are drilled through the slab in the locations which are most likely to give the best result for installing the slab lifting product.

Holes may be drilled as needed throughout the job in different locations in order to jack up the slab with the best result.

Step 02

Slab Lifting Injection Gun

Using a special concrete slab lifting injection gun, the process of injection is initiated.

The injection is done with patience so the position of the slab can be monitored on all sides throughout the concrete lifting process.

Step 03

The Possible Seesaw Effect When Slab Lifting

As more polyurethane is injected the slab will begin to lift.

Often a slab can teeter like a seesaw as the polyurethane is injected. This seesaw effect is balanced out by careful placement of the injection ports.

Additional injection ports are drilled during the injection process if they are needed.

Step 04

Over-Lifting of Slabs during the Injection

As the concrete slab lifting process lifts the slab closer to the termination point, the injection will be slowed to make sure that the slab is not over-lifted.

Over-lifting is when too much product is injected through the slab, jacking it up higher than needed.

Step 05

Final Touches of Lifting The Concrete Slab

As the slab arrives at the desired jacked height, the slab jacking gun will be disengaged and the slab jacking technician will leave the equipment in place while the polyurethane hardens to see if the slab needs any further fine tuning.

Step 06

Cleaning After Concrete lifting

The concrete slab lifting equipment is removed and the work area is cleaned.

Step 07

A Note on Injecting of a Driveway Slab

Finally, the injection ports will be patched with a waterproof grout as needed.

We often use coloured oxide in our patching grout to match the colour of your slab as close as possible. If you are planning to paint or resurface your slab then we suggest you do your concrete slab lifting beforehand as the patching may be a slightly different colour.

Driveway slabs can be used for normal vehicle traffic within 15 minutes of completion.

Select the boxes that describe your problem best

Why Does Concrete Sink?

soil subsidence.

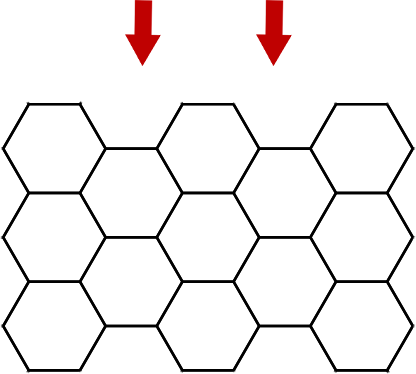

See below, the same number of hexagons are in each illustration to show how mechanical compaction does not compact the sand and soil below a slab as efficiently as being saturated with rain water over time.

Mecahnical Compaction

Disorganised

(Higher Volume)

Hydraulic Subsidence

Organised

(Lower Volume)

In some cases, soil, sand and aggregate can also be washed away by flowing water beneath the concrete slab which causes a cavity to form below the concrete slab or footing.

Select the boxes that describe your problem best

Concrete Slab Lifting with

Polyurethane

Polyurethane is a type of polymer that is used in a variety of applications, including concrete slab lifting. Polyurethane is a long lasting product that has withstood the test of time. Its advantage with slab lifting is, it is fast to install and cost effective. Concrete slab lifting is a process in which polyurethane is injected under a concrete slab in order to lift it back to its original position or to level it out.

The process of slab jacking using polyurethane works as follows:

1

Small holes are drilled through the concrete slab in strategic locations.

2

As the polyurethane is injected, it expands and lifts the slab.

3

A hollow needle is inserted into each hole and polyurethane is injected under the slab.

4

The polyurethane cures and hardens, forming a solid support beneath the slab.

The scientific principle behind this process is known as buoyancy. When an object is placed in a fluid, it experiences an upward force called the buoyant force. This force is equal to the weight of the fluid that the object displaces.

In the case of slab lifting, the polyurethane acts as a fluid and is injected under the slab. As it expands, it displaces the soil beneath the slab, creating an upward force that lifts the slab. The strength and stability of the polyurethane support is determined by the amount of polyurethane injected and the pressure at which it is injected.

Overall, the use of polyurethane in slab lifting is a effective and efficient way to lift and level concrete slabs. Its ability to expand and lift the slab is based on the scientific principle of buoyancy, and it provides a durable and long-lasting solution for correcting slab settlement issues.

The History of

Concrete Slab Lifting

In the past, concrete slab lifting was typically performed using a mixture of concrete and sand, which was laboriously mixed by hand and injected under the slab using a hand pump. Today, modern slab jacking techniques often use specialized equipment and materials, including polyurethane foam and hydraulic pumps, to lift and level concrete slabs more efficiently and effectively.

Overall, concrete slab lifting is a proven and effective technique that has been used for many years to repair and level sunken concrete slabs. Its use has evolved and improved over time, and it is now a widely used method for repairing and maintaining concrete surfaces.

Concrete slab lifting, also known as mudjacking or slab jacking, is a process that is used to lift and level concrete slabs that have settled or sunk due to soil movement or other factors. The technique involves injecting a high density polyurethane foam under the slab, which fills voids and lifts the slab back to its original position.

The history of concrete slab lifting can be traced back to the early 20th century, when the technique was first developed as a way to repair and level sunken concrete slabs. Over time, the technique has evolved and improved, and it is now widely used to repair a variety of concrete surfaces, including driveways, sidewalks, patios, and foundations.

Select the boxes that describe your problem best